Researchers at the University of Kentucky Center for Applied Energy Research (CAER) have developed a method to turn Kentucky waste coal into valuable carbon products.

Kentucky is the seventh-largest coal-producing state in the nation, mining millions of tons each year. After mining, coal is sent to a preparation plant where it is sized and separated for shipment. As part of that process, a stream of coal unsuitable for transportation, called waste coal, is produced and stored onsite. More than four billion tons of waste coal are estimated to exist across all Kentucky coalfields.

The technology employed at CAER shows great promise for building a cost-competitive, domestic supply chain for carbon fiber and graphite, strategic materials that are increasingly important to our global economy.

CAER researchers were able to take what is an environmental liability — impounded waste coal — and turn it into a highly sought-after strategic material that is critical to the nation’s transportation, national security and renewable energy sectors.

“The University of Kentucky is constantly making waves in the scientific field, whether it’s advancements in energy, agriculture or defense. Today’s exciting breakthrough is a testament to the incredible work being done by the UK CAER research team as they revolutionize how coal is used. This is not only fantastic news for the university, but it’s also a big win for the thousands of coal workers whose livelihoods depend on Kentucky’s strong coal industry. As Senate Republican Leader, I’m proud to have been a partner in our Commonwealth’s research endeavors, and I’m eager to see how this talented team will build off of this progress,” said U.S. Sen. Mitch McConnell, who has worked closely with UK to support this project.

This CAER research was supported by the U.S. Department of Energy (DOE) Fossil Energy and Carbon Management Office in collaboration with Oak Ridge National Laboratory.

The project “C4WARD: Coal Conversion for Carbon Fibers and Composites” focuses on developing the fundamental and translational science and engineering necessary to create energy-efficient and cost-effective processes for manufacturing carbon fibers and graphite from coal with tunable properties.

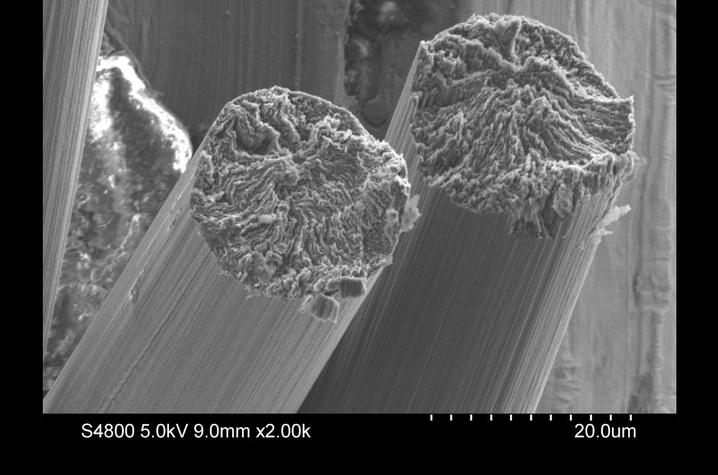

A key technical advancement was the development of a viable process to convert coal to a filtered liquid, and then convert that liquid into mesophase pitch — a liquid crystal material that can be converted to highly ordered carbon fiber with very high stiffness. It can similarly be used to produce graphite powders.

In this breakthrough, high modulus carbon fibers were produced from the waste coal, meaning they have a high stiffness-to-weight ratio. Nearly half of the carbon comprising the fibers stemmed from the waste coal.

“Carbon fiber and graphite are essential to any energy transition,” said Rodney Andrews, CAER director and principal investigator for C4WARD. “We believe this technology has a real opportunity to create new jobs and boost economic opportunities in Kentucky coal communities as demand for carbon fiber and graphite continues to grow.”

This project was spearheaded by CAER’s Carbon Materials Group, guided by Andrews and CAER Associate Director Matthew Weisenberger. CAER is a global leader in developing carbon fiber from a variety of sources and is home to the largest carbon fiber spinline facility at any academic institution in North America.

I continue to be inspired and motivated by the outstanding research and discovery taking place at CAER. However, we would not be in the position to conduct such groundbreaking work without the consistent and strong support of Sen. Mitch McConnell. Sen. McConnell has long championed our energy research and development efforts and was one of the very first people to support this particular project. We remain grateful for his leadership.”

UK President Eli Capilouto

The C4WARD project stands at the convergence of two of the university’s research priority initiatives, which challenge Kentucky’s top researchers to focus on the Commonwealth’s most pressing issues. This project is crucial to UK’s existing Energy Research Priority Area and UK’s newly created Materials Science Research Priority Area (RPA). The goal of the RPA is to find innovative solutions to address industry challenges and position the Commonwealth to become a global leader in a competitive materials market.

“Materials are critical to our future, and the University of Kentucky is committed to ensuring Kentucky is well-positioned to make a major impact in this evolving marketplace,” said Lisa Cassis, UK vice president for research. “From manufacturing electric vehicles and next-generation electronic devices or developing new battery technology or energy storage systems, we are going to need new ways to harvest these materials from domestic sources. We are working to ensure the state’s flagship university is here to partner and add value to these industries in Kentucky.”