When people discuss the best ways to make our buildings more sustainable, folks in the know will usually talk about energy and water efficiency, indoor air quality and maybe something a little more esoteric, like biophilic design. These are all valuable pursuits on their own terms, but what if I told you that there was a huge, sneaky source of greenhouse gas emissions associated with most buildings before they even get connected to the grid and begin using power?

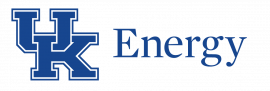

With the impacts of the climate crisis beginning to become apparent in the form of 3 “100-year floods” in the span of a decade or 100-degree temperatures in places that recently never needed air conditioning, the need to understand how carbon gets into the atmosphere has never been greater. According to Architecture 2030, 39% of yearly greenhouse gas emissions are associated with buildings, but within that very large figure, building operations only account for 28%. So, what gives with the other 11% of the building sector’s emissions? Well, take a moment to think about a large construction site. Most construction is about assembly. Erecting steel, pouring concrete, installing insulation, and placing windows are all about putting the right components in the right places. The simple questions of “where do those components come from?” and “how are they made?” begin to point us to the missing 11% of yearly global carbon emissions.

Each of these materials, as well as almost anything else in a building, lives a life that begins with raw material extraction and refinement, production, and delivery. With each phase of making these building materials, energy (often non-renewable) is used, and quite a lot of it. Just the process of making concrete, by some estimates, accounts for 8% of yearly emissions. The carbon associated with making these materials is called “Embodied Carbon,” and represents a new and only recently measurable frontier for building sustainability.

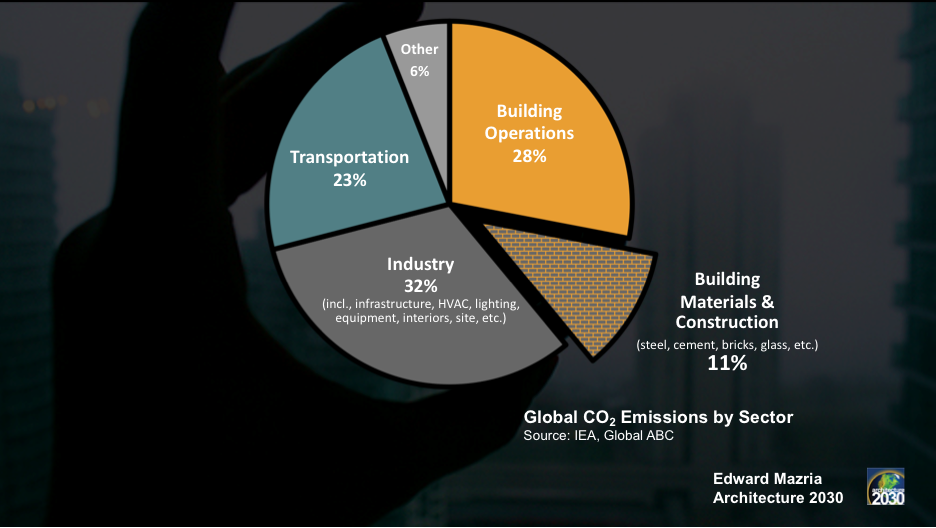

So why is embodied carbon so important, when building operations still represent more than double the footprint of building materials each year? Well, the best answer is that it all matters, but there’s still more nuance to explore. The IPCC has set a target limiting global temperature rise to 2 degrees Celsius by the year 2050 to avoid the very worst effects of climate change. That gives humanity an ever-shrinking window to try and get this right, placing an urgency of avoiding or reducing “big ticket emissions” now. Take a look at the following graph. It represents the embodied and operational carbon emissions associated with an average commercial building constructed in 2020.

That means that between 2020 and 2050, our “things get really ugly” date, that the amount of embodied carbon released in the process of construction is roughly equal to 30 years of operational carbon. Essentially, just about every new construction project releases a very large burst of carbon, but fortunately, there’s been a great deal of progress in finding ways to address embodied carbon.

First of all, concrete and steel are the big-ticket carbon items in most commercial projects. The emissions associated with making concrete account for roughly 8% of yearly emissions. With steel, as you can imagine, extremely high temperatures are required in both the refinement and shaping stages. These are long-lasting, high-performance materials, so often the best architectural solutions involve designing for evolving uses of a building so that they avoid needing to be replaced, whenever possible. Architecture programs like Tally, One Touch and Athena do an excellent job finding the areas where embodied carbon can be saved in a project. Another exciting front is around mass laminated timber, which can allow safe construction up to 12 stories out of wood, which can help to turn the structure into a carbon sink.

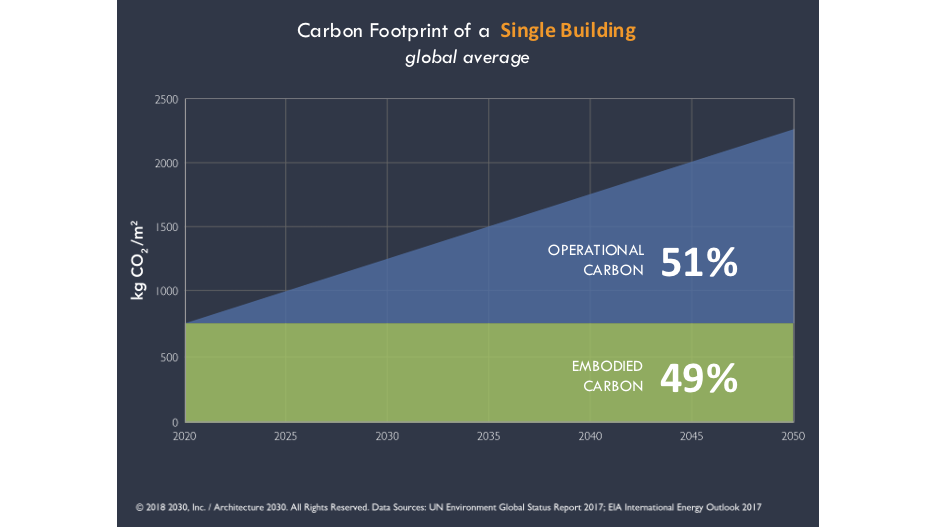

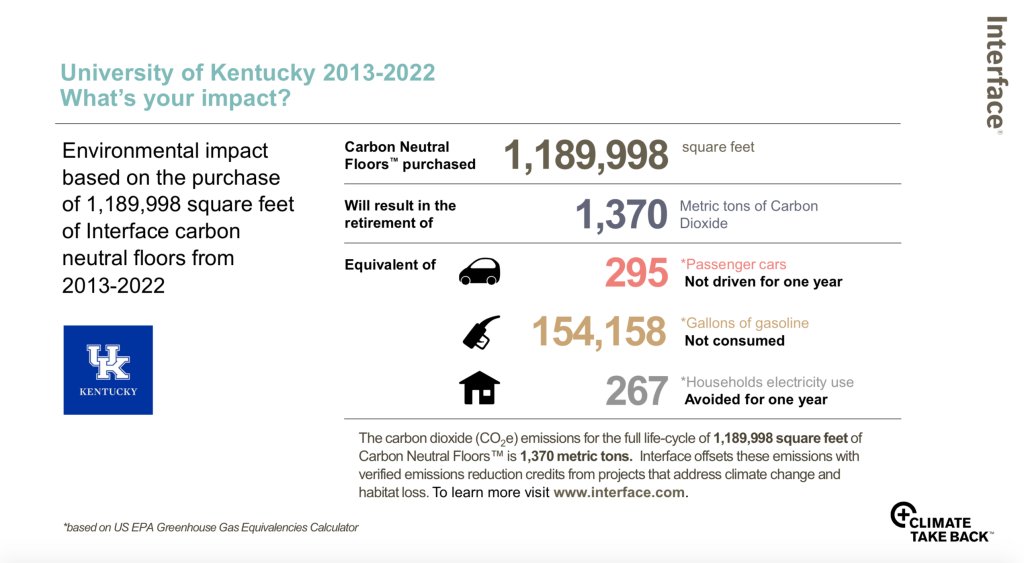

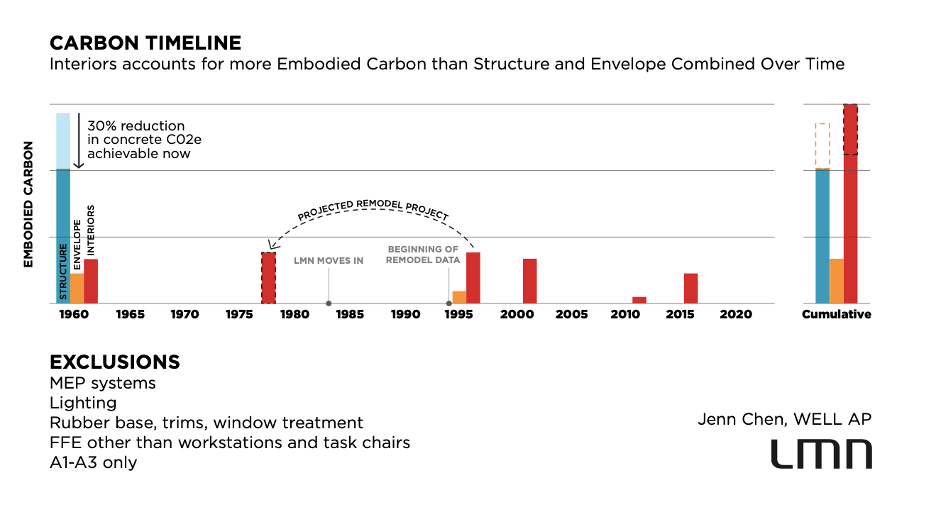

Interior finishes have role to play here as well. Traditionally, when the energy efficiency of a building was the major criteria for its sustainability, finish selection had a reduced role compared to materials like insulation. Through the lens of embodied carbon though, the interiors take on a higher degree of importance because these materials are typically changed every 10-20 years, which adds up as you can see below.

Calculators, like the Embodied Carbon in Construction Calculator (or EC3 tool), have added a new level of transparency in this industry by collecting the global warming potential of different manufacturers within a product category from publicly available documents. For building owners with carbon goals, like UK, data like this allows them to set new targets and specifications that include embodied carbon. What a great way for a public institution to create a living laboratory to help suppliers move in a more sustainable direction!

In the second part of this blog post, we’ll dive deeper into some of the ways suppliers and owners are working to tackle embodied carbon. The solutions take many forms that range from the simple to the technical, but most are ready to go today, and not necessarily more expensive.