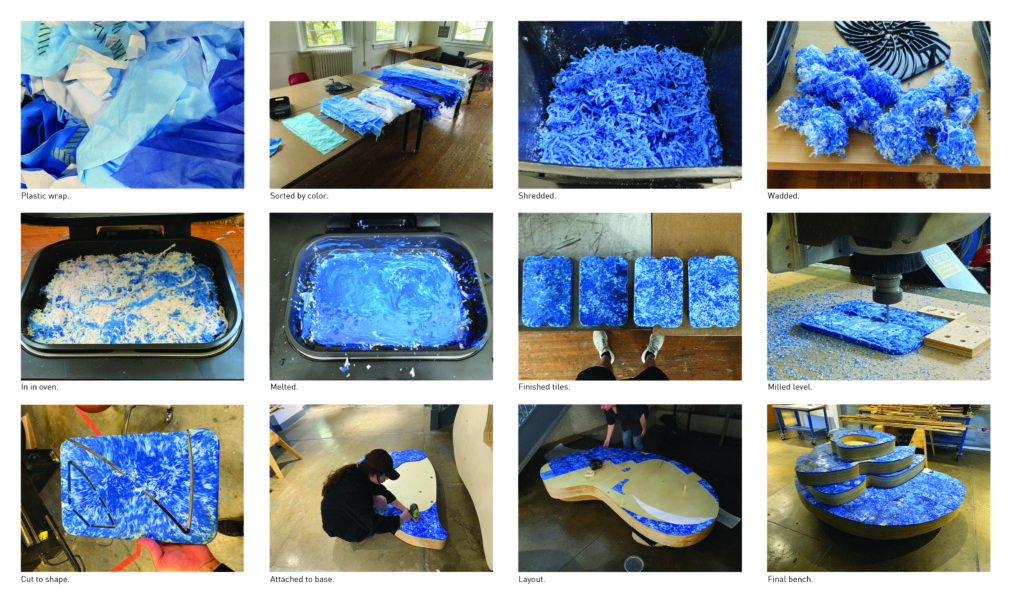

The Big Blue Bench (figure 1) is a furniture piece and public art installation that serves as a prototype to demonstrate the reuse of plastic waste as building material (figure 2). The product is one result of a multidisciplinary effort funded by the 2021 UK Sustainability Challenge Grant Program to explore new uses for the abundance of discarded plastic produced by UK Healthcare. This student-led design-build effort also serves as a model for designing and building with sustainability in mind. In December of 2023, the bench will be moved from Pence Hall to the Cornerstone Exchange.

The project funded by the program was initiated by a team comprised of members from multiple departments and is titled “Turning Plastic Waste into Fuel for Operating Campus Grounds Equipment: Engineering and Designing Sustainable Solutions to UK’s Plastic Waste Issue,” which proposed a process to convert discarded plastic IV bag wrappers from UK Healthcare into clean fuel and included a design component to produce interactive installations to bring attention to the issue of plastic waste on campus.

This design proposal was developed over the course of the Spring 2022 semester in a design build elective, Fabricating Play, offered in the College of Design by Associate Professor of Architecture, Jason Scroggin. The class explores the use of the systematic processes of digital design and fabrication directed towards the development of large-scale interactive objects. These constructed objects consider the relationship to human scale and proportion, materiality, and method of fabrication and assembly. The project evolved through research, discussion, and fabrication over the course of fourteen weeks.

For the course, the project serves as a tool to teach students about the potential of incorporating recycled material into their design proposals and as a proof of concept to demonstrate a design process and philosophy of designing and building with material conservation and reuse in mind. The potential of this process and philosophy is that it could be translated to apply to multiple materials and scales of building.

The class was charged with developing concepts for use and new implementation of this plastic waste generated by UK facilities on campus with a focus on single use plastics discarded from university healthcare. The students began with a tour of the recycling facilities (figure 3) to understand the amount of waste produced and discover potential materials for use in their proposals. After experimenting with multiple materials, they selected a blue plastic wrap which is used to keep equipment sterile before its use and is produced in box loads daily generating a near limitless supply (figure 4).

The design proposal selected (figure 5) by the class featured a large bench that provided a communal “island” for working and relaxing to be placed anywhere on campus. It is a set of horizontal shifting and undulating plates allowing multiple zones of varying sizes for sitting and holding a variety of items from laptops to coffee cups.

This object could be broken down into three smaller furniture pieces (figure 6) that would serve the same purpose creating a larger area of distribution and encouraging more movement and interaction between the users. One of these pieces has been fabricated for installation at The Cornerstone building on campus (figure 6).

The final fabrication is entitled Big Blue Bench (figure 7). It may be considered an art piece, demonstrating the reuse of the discarded material on its topmost surfaces satisfying the needs of the Sustainability Grant Challenge, and a functional bench and table for students to use, satisfying the design build requirements of the course.

The top layers of the Big Blue Bench are comprised of 106 custom cut tiles produced from the CNC milled blanks. The blanks are created by shredding the plastic wrap into small strands that could be easily melted into the tray of a small electric grill (figure 8).

The surgical blue wrap utilized for this project is a made with polypropylene which has been estimated to account for 19 percent of all operating room waste. The blue wrap is recyclable due to its thermoplastic nature and one of the safest plastics to melt.

The project helped students confront the issue of plastic waste. By engaging this project, they also learned about the underutilized departments that manage waste and recycling on campus and how to better engage them in their future projects.

Spring 2022 Course Students

Kevin Hernandez, Drake Howard, Jackson Karnes, Sydney Lough, Steve Ngandu-Sankayi, Parker Selin, Emily White

Student Assistants Summer 2022 – Fall 2023

Kay Bailey, Mariana Mesa Castillo, Nathaniel Cooper, Trey Davis III, Chase Faulkner, Qamar Ghazi, Kyle Heffernan, Destiny Laing, Chris Marra, Pasha Mohaghegh, Melisa Nava, Anemone Rishel, Benjamin Rudloff, Miles Smith

This project could not have been completed without the help and support of the Challenge Grant Team UK Office of Sustainability, Facilities Management, and the entire CoD FabLab team including:

Joe Brewer, Director of Technology and Facilities

Sophia Thomas, Fabrication Lab Manager

Alec Whisman, Design Technology Specialist

We would also like to thank:

Hannah Jackson, Design Tech Specialist, Pooya Mohaghegh, faculty in Product Design, and Owen Sadrzadeh, faculty in Interiors, for fabrication tutorials and shop assistance in the early stages of the project and John Maddox, Associate Professor of Mechanical Engineering, for assistance in testing early tile prototypes.